Methodology

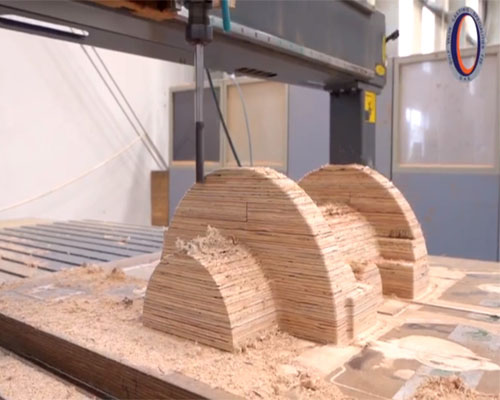

PATTERN SHOP

All casting drawings are verified by the MAGMA simulation software before the process begins. The process is well defined and noted to each department before it starts.

Gulf valve casting Specialties Pattern shop features highly trained pattern makers from the simple to the extremely complex casting design.The are stored safely after production racked in fully covered area. The total covered area for pattern storage is 2,500 Sq Meters.

Handling currently 2000 active patterns and can accommodate 2000 more.